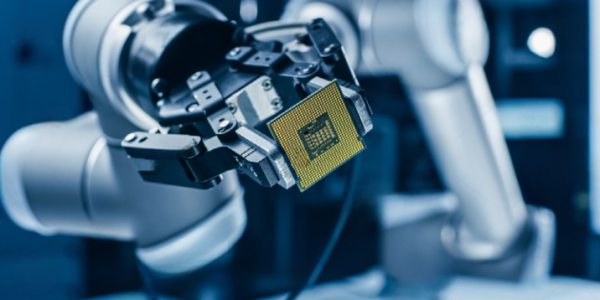

Assembly & Testing

Key points of our Assembly and Test solutions

Thanks to flexible assembly lines, we offer robotic solutions even if your product range is high. In this way, your production lines are almost unaffected by future new products, possible product changes and revision processes.

By performing post-assembly tests, we ensure that you produce standard and quality products.

Together with our experienced suppliers and partners in the field of design, engineering calculations and manufacturing of many equipment such as servo motors, slides, rail cars, linear (cartesian) systems, gears, belts, pulleys, fixtures, moulds, stands, servo conveyors with fixtures which complete the robotic systems we are doing.

We can offer different automatic bonding systems such as polyurethane (mastic), hot melt, silicone in your different parts joining applications. Again, with ultrasonic welding devices, we can bond plastic materials together by welding.

Other assembly applications that we frequently apply are putting washers, bolts and nuts through automatic tightening systems. In these structures, we can benefit from vibrating (vibrating) bowls and flexible feeding systems, which we also do R&D.

We can respond to systems that still require sealing by assembling o-rings and gaskets.

Testing for accuracy and quality control after assembly operations are complete is critical. Thanks to the test and control systems we offer, you will experience the comfort of producing high quality, standardized products. We frequently use high resolution cameras, probes and poke yoke methods in quality control.